Visit our Blog and Subscribe!

As a wholesale supplier, we understand that our customers prefer to market our products with their own brand. To do so is simple:

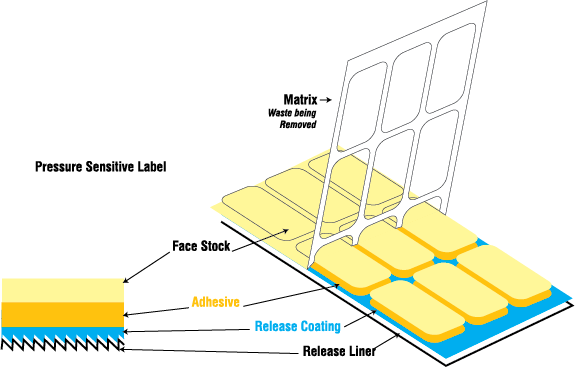

Labels that are permanently tacky and bond to surfaces with a minimum of pressure are called pressure sensitive or self-adhesive labels. These labels offer benefits over wet glued, heat-seal or water remoistened labels. The key benefit is the ability to bond to a wide array of surfaces such as plastic and corrugated containers and packaging films. They are also simple and convenient to use and require minimal machine modification, preparation or cleanup.

It’s called “pressure sensitive” because all it takes is a little pressure to effect instant, all-over bonding. Unlike other types of labeling, pressure sensitive labels require absolutely no fasteners, glue, water or heat. To apply, just pull away the liner from the face stock...and press directly onto the item you are labeling. Result? Instant adhesion with only

|

|