Visit our Blog and Subscribe!

As a wholesale supplier, we understand that our customers prefer to market our products with their own brand. To do so is simple:

DIAGONAL SEAM

A seam running diagonally from the bottom fold and corner, up to the throat of an envelope. Frequently used in commercial open side envelopes, as well as announcement, invitation and baronial envelopes.

DIE

A precision tool used to cut out envelope blanks, windows or other shapes.

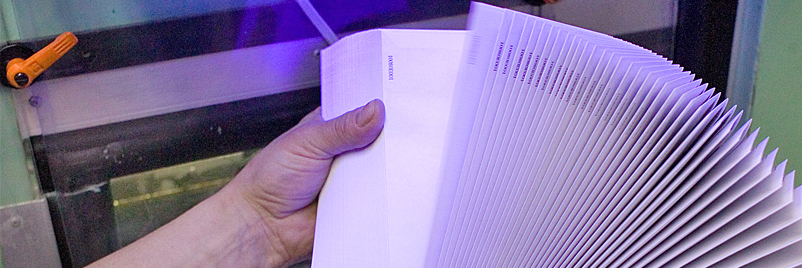

DIE CUT ENVELOPE BLANKS

The paper cut into the shape of an envelope before it's folded.

DIE CUTTING

Refers to a mechanical press operation used to punch a shape out of paper.

DOT GAIN

A printing defect in which "dots" print larger than they should, causing darker tones or colors.

DRILLING

Precision piercing of stacks of paper or envelopes. Interoffice and bank teller envelopes are often drilled to ensure that all contents are removed by the recipient.

DRY OFFSET (LETTERSET) PRINTING

A method of printing where ink is applied to a slightly raised plate, transferred to a blanket, then transferred to the paper. Similar to wet offset, but requires a coarser screen, normally 100 to 120 lines per inch. Produces printing quality higher than flexography but lower than wet offset.

DUMMY

A hand folded mock-up of a piece of material to be printed that has exact specifications.

EMBOSSED FINISH

A finish or pattern applied to paper.

ENVIRONMENTALLY FRIENDLY

Refers to envelopes made from grades of paper that contain a percentage of recycled material.

EXTENSION FLAP

A relatively small flap parallel to an envelope's opening. It has no seal or scoring and is not folded down.

FACE

The side of the envelope without seams.

FACER-CANCELER

The machine that will automatically face letter-size mail in a uniform orientation and cancel the stamps.

FACING IDENTIFICATION MARKS (FIMS)

A series of vertical full bars printed in the upper middle portion of a mail piece, just to the left of the indicia. FIMS are used to identify business reply mail, courtesy reply mail and other barcoded mail.

FELT SIDE

The top side of the sheet on the paper making machine; usually the preferred side for printing.

FIMS

Facing Identification Markings (see above).

FLAPS EXTENDED

Leaving the envelope's seal flaps in a vertical position (not folded down).

FLAPS FOLDED DOWN

When flaps are folded down against the back of an envelope.

FLEXOGRAPHY

A printing process that uses a raised image area, inked by an anilox roll, to press directly against the substrate to produce the image. Flexo inks are usually water based and are very fluid, fast-drying inks. This allows for very high running speeds.

FONT

All characters of a particular type.

FOUR-COLOR PROCESS

A printing and reproduction of full color images using the four process printing colors—yellow, cyan, magenta and black—to create a full-color, continuous tone image.

GLASSINE

Translucent, cellulose based paper.

GRAIN

The direction in which most of the fibers lie in a finished sheet of paper. Paper folds more easily with the grain.

GRAIN LONG

A term used to designate that the grain of the paper is parallel to the longest measurement of a sheet of paper.

GRAIN SHORT

Grain of paper runs at right angel to the longest dimension of the sheet.

GUM

The adhesive that seals an envelope. The most common envelope gums are: Seal Flap Gum, Back Seam Gum, Patch Gum and Latex Gum.

GUMMER "SEAL"

A rubber roller that rolls on an envelope's seal gum.

GUMMER "SEAM"

Made of brass or block synthane material, seam gummers apply gum to the side flaps of envelopes. The newest applicators are high speed spray nozzles that are triggered by an electronic eye.

GUMMER "WINDOW"

Window gummers are made to fit the window size and patch. They allow the window material to be applied at high speed.

GUSSETS

Envelopes with expanding accordion pleats for extra capacity.

HALFTONE

A method of screening a continuous tone image (like a photograph) for printing or reproduction. The dots in the screen vary in size and density to recreate the complete range of highlights, low lights, and mid-tones of the original image.

HAND CUTTING

A process of cutting envelopes by hand placing the die in a precise position on a lift of paper. This is often done for short run converting work.

HAND FOLDING

Orders as small as 100 can be die cut and folded by hand, including seam gumming and flap gumming. This is most often done to make custom "King Size" envelopes.